PADMINI INNOVATIVE MARKETING SOLUTIONS PVT. LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to PADMINI INNOVATIVE MARKETING SOLUTIONS PVT. LTD.

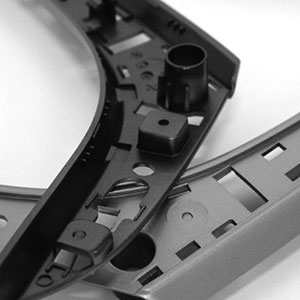

Polyamide (Pa)

52571.jpg)

Features:

Nylon 6-6 is frequently used when high mechanical strength, great rigidity, and good stability under heat is required

Nylon 6/6 is one of the most versatile engineering thermoplastics.

excellent balance of strength, ductility and heat resistance,

Nylon 6/6 is an outstanding candidate for metal replacement applications.

Nylon 6/6 is very easy to process with a very wide process window. This allows it to be used for everything from complex, thin walled components to large thick walled housings.

Nylon 6/6 is very easy to modify with fillers, fibers, internal lubricants, and impact modifiers. With the use of fiber reinforcements, the physical strength of nylon 6/6 can be improved five times that of the base resin.

The stiffness of nylon 6/6 can be improved up to 10 times. With impact modifiers, the ductility of nylon 6/6 is comparable to polycarbonate.

The use of internal lubricants improves on the already excellent wear resistance and friction properties on nylon 6/6. Its versatility allows it to be used in almost any application that requires high physical strength, ductility, heat resistance and chemical resistance.

Good mechanical and impact resistance

Colourability

Used in high temperature environments

Heat stabilize systems allow sustained performance at temperatures up to 185°C (for reinforced systems).

Applications:

It is used for ball bearing cages, electro-insulating elements, pipes, profiles and various machine parts

Power tools

Cables

Furniture

Protection equipments

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.

52563.jpg)

52568.jpg)

52571.jpg)

52572.jpg)

52575.jpg)